Alumina Ceramic

KCM Technology

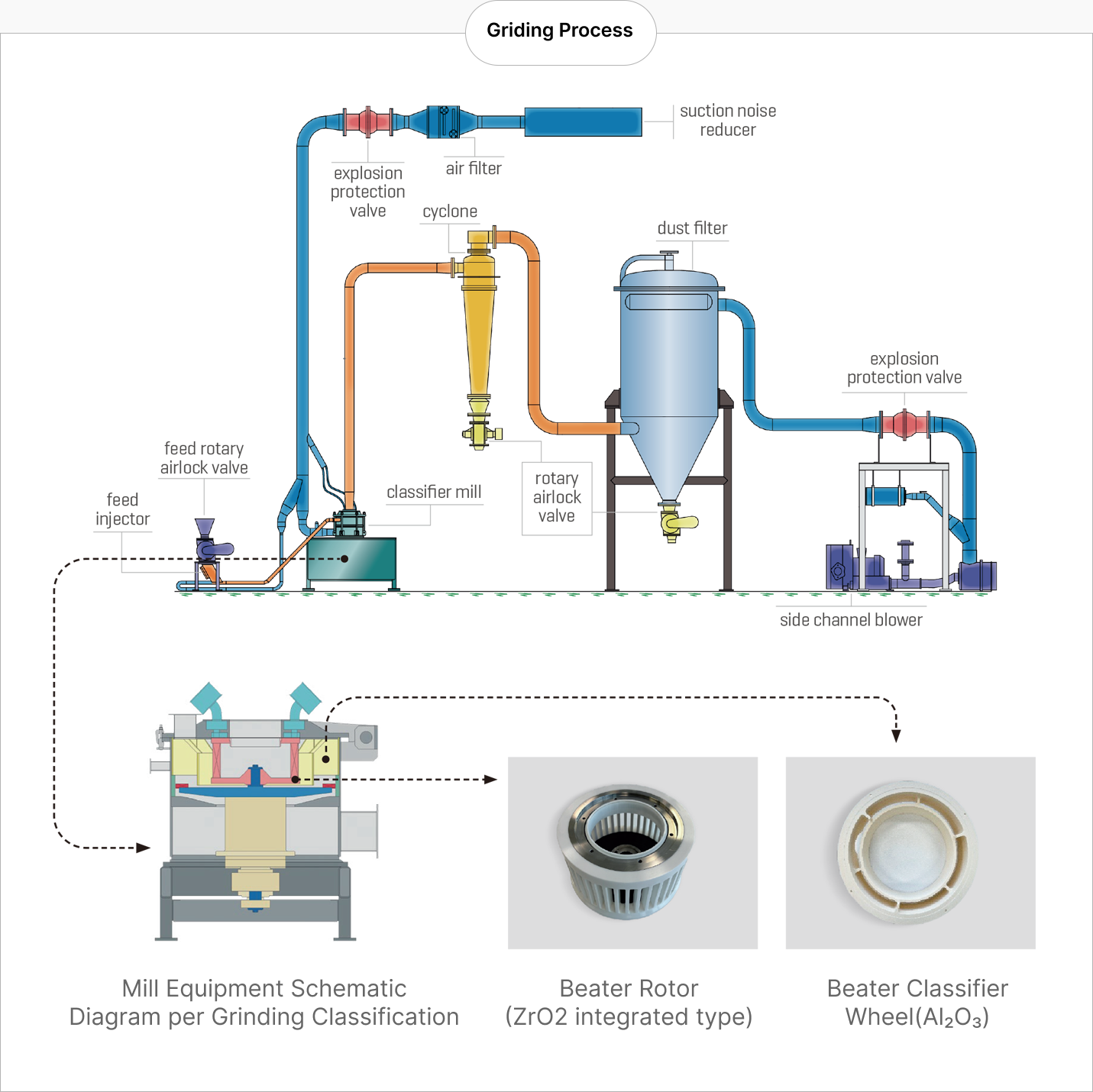

Ceramic for Equipment used in Grinding Cathode Materials for Secondary Batteries

The manufacturing process of cathode materials for lithium-ion secondary batteries includes a grinding process that finely crushes the condensed reactants to the desired particle size. At this time, the grinding process utilizes a mechanical impact method that occurs between a grinding track installed circumferentially inside the equipment and a high-speed rotating rotor. Previously, metal products were used inside the classifying mill, but the high wear rate of the metal itself and the resulting contamination resulted in significant problems. Therefore, there is a new trend to use ceramic (Al2O3, ZrO2) products with high wear resistance characteristics.

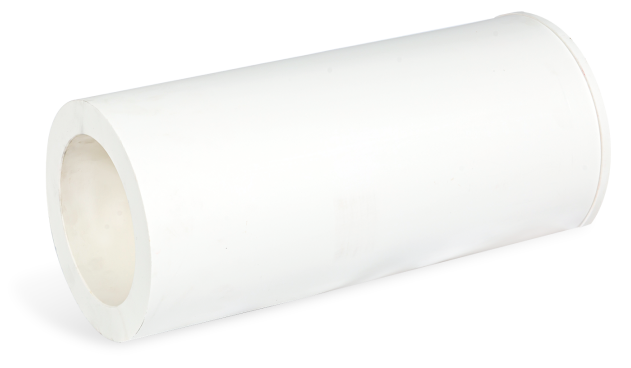

96% Al2O3 Ceramic

It is cheaper than high purity (over 99.8%) Al2O3 and has excellent abrasion resistance and heat resistance so it is frequently used a grinding roller, as general industrial parts, as well as parts for pipes and machines for transferring thermoelectric power plant coal cinders.

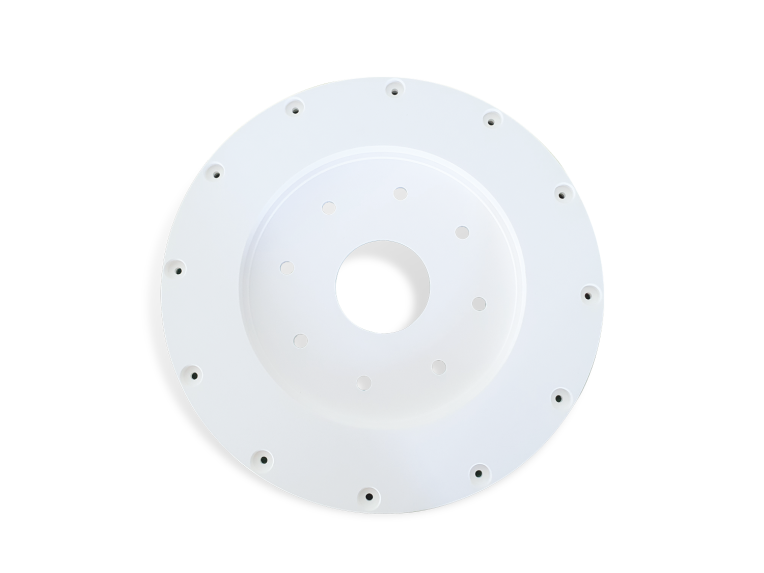

ZTA(Zirconia Toughened Alumina)

ZTA is a material that has higher strength and toughness than alumina at lower cost.

It is resistant to corrosion and erosion, and has destruction toughness so it is used for wear resistant parts including insulators, parts for pumps, bushings and impellers.